×

×

Being able to bend sheet metal is an important tool if you plan on working with metal. Thin sheet metal can more easily be shaped, but is harder to get it done the right way if you are unfamiliar with how to bend. Sheet metal bending is also a nice skill to add up in your list if you can bend sheet metal quite well there are many amazing things which could be produced through this form such as Metal art, parts for cars or even furniture. Not bending sheet metal like a pro?

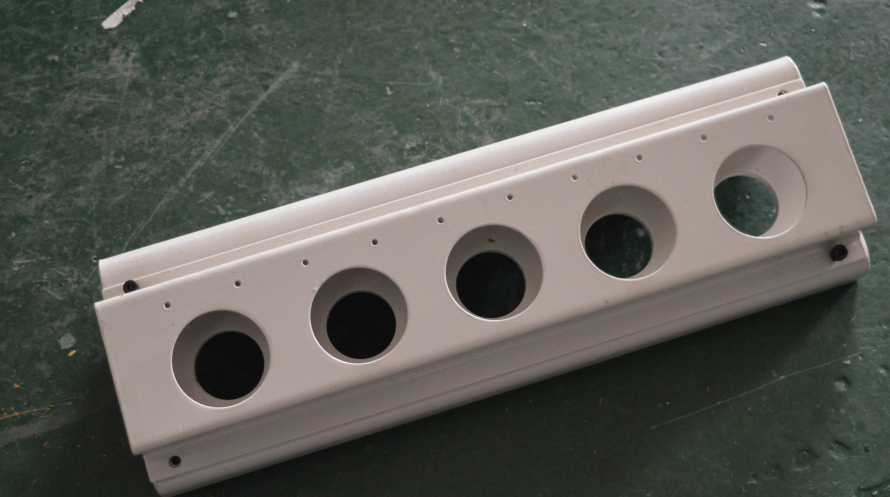

There are a lot of ways you can bend sheet metal, so one method may not be the best for all situations. Using some of these tools and techniques will give you more options when it comes to bending steel with precision. A brake press is essentially a machine that helps you bend the metal into angles and curves -- essential for creating good shapes. First,you can check and measure the size of metal piece you want to bend so that it must be fit according to your requirement. You also have to decide which way you want it bent, be sharp angles or more smooth curve. Once you have your numbers measured, simply adjust the brake press to form the optimal curve.

Tip number two for bending sheet metal: never be without the right tools! If your metal is very thick, you will have to use a big and burly brake press. However if you are bending small sheet metal gauge thicknesses (maybe gauges latter on tubes) with our brake presses, then a lighter model will suffice as well. The biggest issue with using the wrong tool is how it can damage your metal parts and cause less-than-ideal bends in areas that may be visible.

When you are dealing with sheet metal, one of the most important thing is your safety. Safety should be a priority, and everyone in the vicinity of your activitya must wear gloves (to keep the hand safe from wood splinters) and goggles to protect their eyes. The metal is also sharp, so use with care; the last thing you want are cuts. It is also a good idea to secure sheet metal with clamps or other opposing media while you are in the process of bending. Helps to hold it in place and that your bends are line up properly.

Sheet metal is all about angles and curves; the more you practice, greater are your chances of perfecting a bend. Having your placement of the metal in the brake press so that it becomes square is what makes right angles. For example, you are making a 45-degree angle then your metal should be at the center of brake press in 90-degrees. From there you can lower the press to where you would like it for 45 degrees. Special equipment, called a die may be used in the brake press to create that angle into more of a curver shape.

If your real wish is to be good at bending sheet metal, here are some things you can do ot help ensure that you learn faster and more effectively. STEP 1: FIND OUT WAYS HOW YOU CAN BEND THE METAL. You can get to learn the basics as well master-caliber strategies by watching numerous videos, tutorials, and guides which are conveniently available online. It is also a good idea to watch some experienced metal workers in action.

Practice bending sheet metal as often a possible. If you have a brake press at your disposal, use this to perform various radius bends for differently shaped parts. The more you play with their radians, the better will be your designing skills. If you do not have a brake press — no worries! However, you can still work sheet metal with basic hand tools - including a pair of pliers or even your hands.

The Bend sheet metal process, starting from the raw material to the inspections of the company and production process inspections, to inspections in the factories of the product as well as maintenance and installation, has been designed to create a complete quality control system: Raw materials are scrutinized in accordance with the requirements of quality of applicable national standards. The installation teams of the company follow the construction process, and regular safety and quality of the installers.

More than 10 technical directors work at WUHAN GYOUNG INDUSTRY CO. LTD. RD Engineers Over 20people. Our RD Team Has Rich Experience and High Quality. We own three Large Producing Plants Capacity From 2ton To 14ton Wheat Flour Consumption of Bend sheet metal International Advanced Processing Equipment. We can offer you the best noodles maker according to your specifications.

G-YOUNG is committed to offering the finest quality machines. Each member of the team is devoted to their work and Bend sheet metal for their every works. The raw materials, the production processes and final products produced by noodle machines will undergo scientific and stringent quality checks. Our expertise and technology are hoped to bring you better products.

WUHAN G-YOUNG INDUSTRY(tm) CO., LTD is a professional exporter and manufacturer which researches, Bend sheet metal and manufactures instant noodle machine and fine dried noodles machines, and related equipment. Our primary products include instant noodles that are fried or not, low-temperature drying noodle lines featuring chain cables and hanging wires as well as fresh noodles production and other noodle equipment.