溶接用直角治具が正確な接合に重要な理由

溶接は、熱を利用してワークピースを接合する重要なプロセスです。このプロセスでは、仕上がりを良くするために、非常に正確な高さと幅の選択が必要でした。 回転治具 製品は十分に強く、長持ちします。この作業では、ミリメートル単位の精度の溶接が求められ、このタイプの精密溶接には、直角ジグと呼ばれる器具が使用されます。

溶接90度治具は、溶接工が溶接の接合部をきれいかつ正確に作るのに役立つため、溶接プロセスにとって重要です。 パレット組立治具 プロジェクト。これらのジグは、コーナーを溶接するときに溶接工が 90 度の角度を保つように作られており、ワイヤ管理によって最終溶接がよりきれいで美しくなります。直角ジグは、溶接の専門家が作業中に金属を固定して安定させるのに役立ちます。これらは、均一で明確な溶接結果を達成するための完璧なガイドとして機能します。

溶接の世界には、さまざまな直角ジグがあり、それぞれが溶接の特定のステップに合わせて設計されています。 検査治具 磁性に応じて鋼鉄にも作用しますが、角度の数は限られています。コーナークランプは金属部品を所定の位置に保持し、溶接中に 90 度の角度が変わらないようにするためにも使用されます。

市販の溶接用直角ジグは多種多様ですが、溶接工は最小限の材料と工具を使って同様に独自のジグを作ることができます。溶接工は、用途に応じて、ナット、ボルト、ドリルを使用してスクラップメタルから独自のジグを作ることができます。このタイプの DIY 方法は、設計において完全かつ無制限の自由を意味するだけでなく、既製のジグを購入する費用を節約できる可能性もあります。

溶接直角ジグは、溶接方法論に強力に統合され、効率的で効果的な溶接作業に役立つ多くの利点を提供します。これらの利点には、セットアップ時間の短縮による効率の向上、一定の結果を得るための溶接位置の精度の向上、および布地の無駄を減らすことによるコスト管理が含まれます。最終的に、溶接直角ジグにより、溶接作業者はコンポーネントの移動やセットアップが不要になり、より迅速に作業し、より正確な結果を得ることができます。

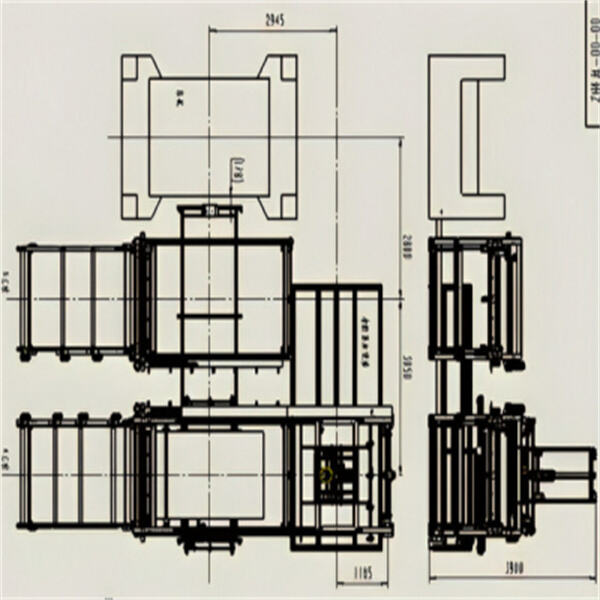

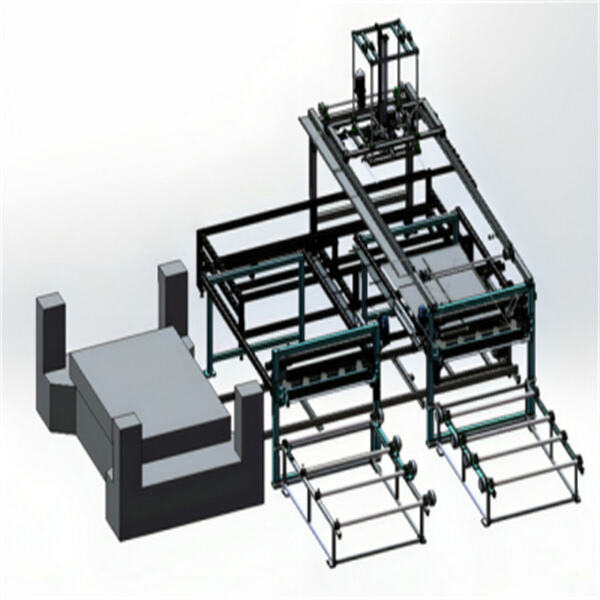

武漢京工業株式会社には 10 名以上の技術ディレクターが勤務しています。研究開発エンジニアは 20 名以上です。当社の研究開発チームは豊富な経験と高い品質を誇ります。当社は 2 つの大規模生産工場を所有しており、小麦粉消費量は 14 トンから XNUMX トン、溶接直角ジグ、国際先進加工設備を備えています。お客様の仕様に合わせて最高の麺製造機をご提供できます。

武漢G-YOUNG INDUSTRY(tm) CO., LTDは、インスタントラーメン製造機、高級乾麺製造機、関連機器の研究、開発、製造を行う専門の輸出業者および製造業者です。当社の主力製品には、揚げ麺と揚げない麺の生産ライン、低温吊り下げ式およびチェーン溶接式直角ジグ乾燥麺ライン、生麺生産ライン、その他の麺製造設備などがあります。

原材料から始まり、社内検査、製造工程中の検査、製品工場検査、設置、溶接直角ジグに至るまで、製造プロセスは品質保証のための完璧なプロセスとなっています。原材料は、関連する国家規格の品質要件に従って精査されます。当社の設置チームは、建設プロセスだけでなく、設置者の定期的な品質および安全性検査も遵守しています。

G-YOUNGの溶接直角治具は、最高品質の機械を提供することに専念しています。当社のチームメンバーは全員、日々の業務に全力で取り組み、責任を負っています。麺機の原材料、製造プロセス、最終製品は、科学的かつ厳格な品質検査を受けます。当社の技術と努力により、より高品質の製品が生まれることを心から願っています。