×

×

Дәнекерлеуге арналған тік бұрышты айлабұйымдар неге дәл қосылыстар үшін маңызды?

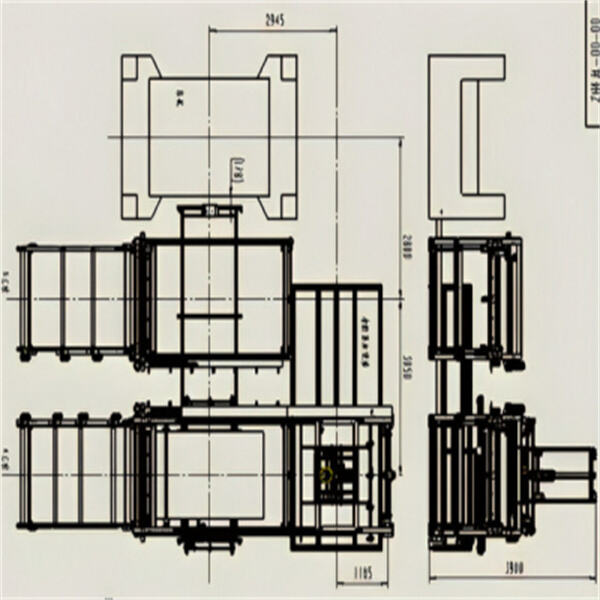

Олардың ішінде дәнекерлеу дайындамаларды жылумен біріктіруге қатысты ажырамас процесс болып табылады. Бұл процесс әрлеу үшін биіктік пен енді өте дәл таңдауды қажет етті айналмалы айлабұйым өнім жеткілікті күшті және ұзаққа созылады. Жұмыс миллиметрге дейін дәлдікпен дәнекерлеуді қажет етеді және дәлдіктегі дәнекерлеушілердің бұл түрі үшін тік бұрышты айлабұйымдар деп аталатын құралдарды пайдаланады.

90 градустық дәнекерлеу айлабұйымдары дәнекерлеу процесінде маңызды, өйткені олар дәнекерлеушілерге ұқыпты және дәл қосылыстар жасауға көмектеседі. паллет құрастыру қондырғысы жобалар. Бұл айлабұйымдар дәнекерлеушіге бұрыштарды бір-біріне дәнекерлеу кезінде 90 градус бұрышты ұстап тұруға мәжбүрлеу үшін жасалған, осылайша сымды басқару соңғы дәнекерлеуді эстетикалық тазартады. Тік бұрышты айлабұйымдар дәнекерлеуші маманға жұмыс кезінде металды бекітуге және тұрақтандыруға көмектеседі - олар біркелкі, нақты дәнекерленген нәтижелерге қол жеткізу үшін тамаша нұсқаулық ретінде әрекет етеді.

Дәнекерлеу әлемінде әр түрлі тік бұрышты айлабұйымдар бар, олардың әрқайсысы дәнекерлеудегі белгілі бір қадамға арналған. Басқа кезде тексеру жабдығы сондай-ақ болат пен темірде олардың магнетизміне байланысты жұмыс істейді, олар жасай алатын бұрыштардың саны шектеулі. Бұрыштық қысқыштар металл бөлшектерді орнында ұстау үшін де қолданылады, дәнекерлеу кезінде 90 градус бұрыштың өзгеруіне жол бермейді.

Сатып алу үшін әртүрлі дәнекерлеу тік бұрыштары бар, бірақ дәнекерлеушілер ең аз материалдар мен құралдарды пайдалана отырып, өздерін жасай алады. Содан кейін дәнекерлеушілер жаңғақтарды, болттарды және қолдану үшін қажет болатын бұрғыны пайдаланып, металл сынықтарынан өздерінің айлабұйымдарын жасай алады. DIY әдісінің бұл түрі дизайндағы толық және шектеусіз еркіндікті білдіріп қана қоймайды, сонымен қатар алдын-ала жасалған айлабұйымдарды сатып алудан ақша үнемдей алады.

Дәнекерлеудің тік бұрышты айлабұйымдары тиімді және тиімді дәнекерлеушілерді жеңілдететін көптеген артықшылықтарды қамтамасыз ету үшін дәнекерлеу әдістемесіне күшті біріктіре алады. Бұл артықшылықтар орнатудағы уақытты азайту, тұрақты нәтижелер үшін дәнекерлеу позициясымен күшейтілген дәлдік және мата шығынын азайту арқылы бағаны басқару арқылы жоғары тиімділікті қамтиды. Ақырында, дәнекерлеу тік бұрышты айлабұйымдар дәнекерлеушілерге жылдам жұмыс істеуге және олардың құрамдас бөліктерін жылжытуды немесе орнатуды қажет етпей, дәлірек нәтижелерге қол жеткізуге мүмкіндік береді.

WUHAN GYOUNG INDUSTRY CO. LTD компаниясында 10-нан астам техникалық директор жұмыс істейді. RD инженерлері 20 адамнан астам. Біздің RD командасының бай тәжірибесі және жоғары сапасы бар. Бізде қуаттылығы 2 тоннадан 14 тоннаға дейінгі үш ірі өндіруші зауыт бар. Дәнекерлеуге арналған тік бұрышты айлабұйымдарды тұтыну бидай ұны Халықаралық жетілдірілген өңдеу жабдығы. Біз сізге спецификацияларыңызға сәйкес ең жақсы кеспе жасаушыны ұсына аламыз.

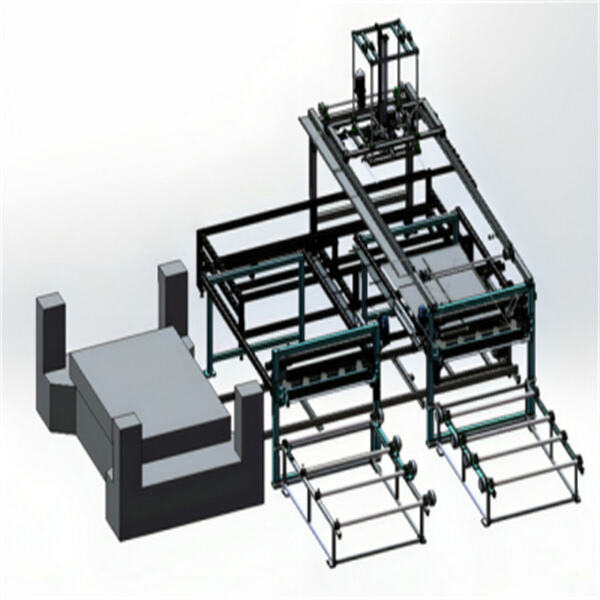

WUHAN G-YOUNG INDUSTRY(tm) CO., LTD - тез дайындалатын кеспе машиналарын және жұқа кептірілген кеспе машиналарын және тиісті жабдықты зерттейтін, жасайтын және өндіретін кәсіби экспорттаушы және өндіруші. Біздің негізгі өнімдерімізге қуырылған және қуырылмаған тез дайындалатын кеспе, өндірістік желілер, төмен температурада ілу және тізбекті дәнекерлеуге арналған тік бұрышты кептіргіш кеспе желілері, жаңадан жасалған кеспе өндіру желілері, сондай-ақ басқа да кеспе өндіру жабдықтары кіреді.

Өндіріс процесі, шикізаттан бастап, компанияның инспекциясы және өндіріс процесіндегі тексерулер, өнімді зауыттық тексерулер арқылы Орнату және дәнекерлеу тік бұрышты айнымалы сапаны қамтамасыз ету үшін мінсіз процеске әкелді. Шикізат тиісті ұлттық стандарттардың сапасына қойылатын талаптарға сәйкес мұқият тексеріледі. Компанияның монтаждау бригадалары құрылыс процесін, сондай-ақ орнатушылардың сапасы мен қауіпсіздігін үнемі тексеріп отырады.

G-YOUNG тік бұрышты дәнекерлеу құрылғысы сізге жоғары сапалы машиналармен қамтамасыз етуге арналған. Біздің команданың әрбір мүшесі жұмыста толыққанды жұмыс істейді және күнделікті жұмыстарына есеп береді. Кеспе машиналарының шикізаты, өндіріс процесі және соңғы өнімдері ғылыми және қатаң сапа тексерулерінен өтеді. Біздің технологиямыз бен күш-жігеріміз жоғары сапалы өнім береді деп шын жүректен үміттенеміз.