Hvorfor rettvinklede jigger for sveising er viktige for nøyaktige skjøter

Blant dem er sveising en integrert prosess for sammenføyning av arbeidsstykker ved hjelp av varme. Denne prosessen trengte svært nøyaktige høyde- og breddevalg for å gjøre finishen roterende jiggfeste produkt sterkt nok og langvarig. Jobben krever sveising som er nøyaktig ned til millimeteren, og for denne typen presisjonssveisere bruker instrumenter kjent som rettvinklede jigger.

Sveising av 90-graders jigger er viktige for sveiseprosessen da de hjelper sveisere med å lage pene og presise skjøter for deres pallemonteringsjigg prosjekter. Disse jiggene er laget for å tvinge sveiseren til å holde en 90 graders vinkel når de sveiser sammen hjørner, slik at trådhåndteringen gjør renere og mer estetiske sluttsveiser. Rettvinklede jigger hjelper en sveiseekspert med å sikre og stabilisere metallet sitt mens han eller hun arbeider - de fungerer som en perfekt guide for å oppnå jevne, bestemt sveisede resultater.

I sveisverdenen er det en rekke rettvinklede jigger, hver designet for et spesifikt trinn i sveisingen. Mens andre inspeksjonsjigg fungerer også på stål og jern avhengig av deres magnetisme, antall vinkler de kan gjøre er begrenset. Hjørneklemmer brukes også for å holde metalldeler på plass, og forhindrer at en 90-graders vinkel endres under sveising.

Det er forskjellige rettvinklede sveisejigger der ute å kjøpe, men sveisere kan på samme måte lage sine egne ved å bruke minimalt med materialer og verktøy. Sveisere kan da lage sin egen jigg av skrapmetall ved hjelp av muttere, bolter og en drill etter behov for bruken. Denne typen gjør-det-selv-metode betyr ikke bare total og ubegrenset frihet i designet, men kan også potensielt spare deg penger fra å kjøpe ferdige pilker.

Rettvinklede sveiser kan integreres kraftig i sveisemetodikken for å levere mange fordeler som letter effektive og effektive sveisere. Disse fordelene omfatter større effektivitet via reduksjon av tid i oppsett, forsterket nøyaktighet med sveiseposisjon for konstante resultater og prisstyring ved å redusere stoffsvinn. Til syvende og sist lar sveising med rett vinkel sveisere jobbe raskere og gi mer nøyaktige resultater ved å gjøre det unødvendig for dem å flytte eller sette opp komponentene sine.

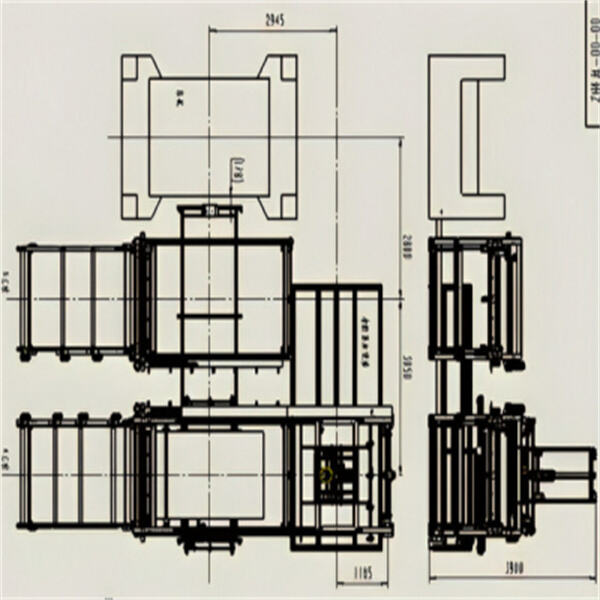

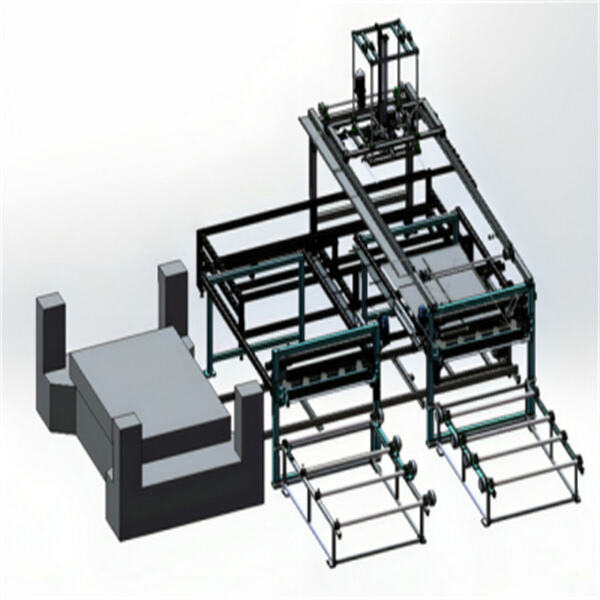

Mer enn 10 tekniske direktører jobber hos WUHAN GUYOUNG INDUSTRY CO. LTD. RD Engineers Over 20 personer. Vårt RD-team har rik erfaring og høy kvalitet. Vi eier tre store produksjonsanlegg Kapasitet fra 2tonn til 14tonn hvetemel Forbruk av sveising rettvinklet jigg Internasjonalt avansert prosesseringsutstyr. Vi kan tilby deg den beste nudler i henhold til dine spesifikasjoner.

WUHAN G-YOUNG INDUSTRY(tm) CO., LTD er en profesjonell eksportør og produsent som forsker på, skaper og produserer instant nudler og fine tørkede nudler maskiner og tilhørende utstyr. Våre hovedprodukter inkluderer instant nudler stekt og ikke-stekte, produksjonslinjer, lav temperatur hengende og kjedesveising rettvinklet jigg tørking nudler linjer, nylaget nudler produksjonslinjer, så vel som annet nudler produksjonsutstyr.

Produksjonsprosessen, som starter fra råvarene gjennom inspeksjoner av selskapet og inspeksjoner under produksjonsprosessen, gjennom produktfabrikkinspeksjoner Installasjon og sveising rettvinklet jigg har resultert i en feilfri prosess for kvalitetssikring. Råvarer granskes i henhold til kravene til kvalitet i relevante nasjonale standarder. Installasjonsteamene til selskapet følger byggeprosessen, samt regelmessige kvalitets- og sikkerhetsinspeksjoner av installatørene.

G-YOUNG sin rettvinklede sveisejigg er dedikert til å gi deg maskiner av høyeste kvalitet. Hvert medlem av teamet vårt er fullt ut på jobb og ansvarlig for sitt daglige arbeid. Råvarene, produksjonsprosessen og sluttproduktene til nudelmaskiner vil gjennomgå vitenskapelige og strenge kvalitetsinspeksjoner. Vi håper inderlig at vår teknologi og innsats vil gi et produkt av høyere kvalitet.