×

×

Welding is a method of creating floods between two parts together, it was done as an operation that fuses metals to each other. But, welding in areas within close tolerances can be difficult. One way to avoid that is by using welding jig fixtures. These important aids contribute to weld accuracy, minimize welding time and allow welders deliver high-quality welded components consistently. This Fugao article informs you about everything regarding the Welding jig fixtures, their different types, how to choose according your project and what modifications can be done for better performance.

Why Welding Jig Fixtures Are Important in Perfect Precision With Injected Molding?

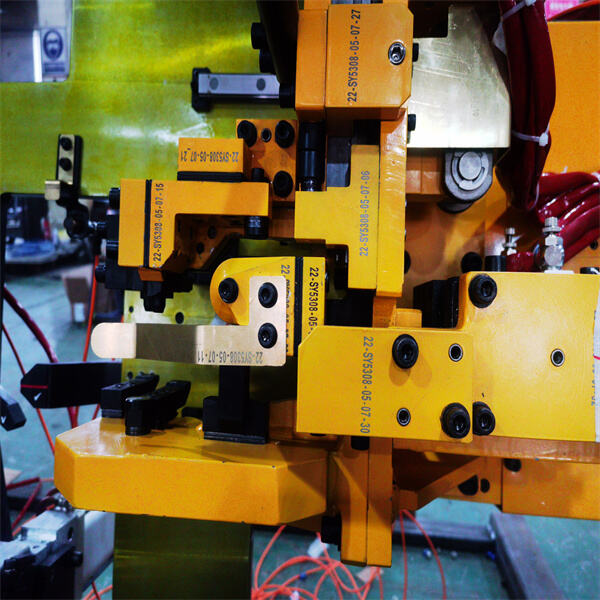

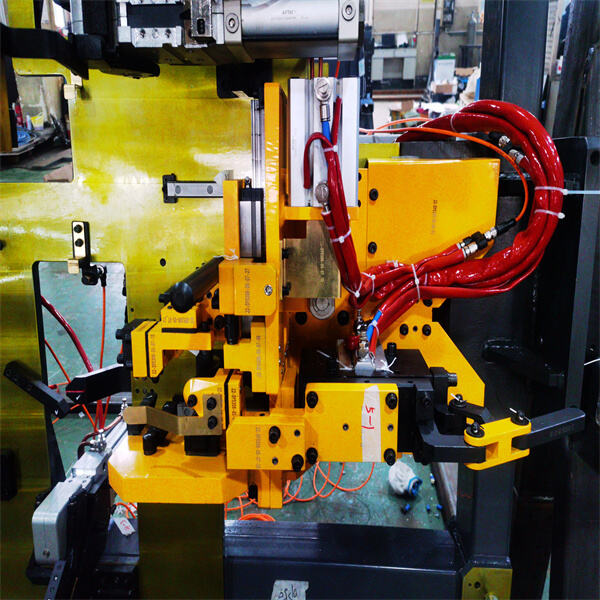

Welding jig fixtures are essential to provide strong welding on components correctly and quickly. These fixtures help in accurate welding by keeping the workpieces securely held while they are being welded There are many types of jig and fixture such, which were designed for the newest needs in welding. Here, we will discuss some of the most popular welding jig fixtures occasionally used during accurate and precise welding;

Clamping Fixtures: These are intended to support the elements being welded which ensures they remain securely in place while welding is carried out. Being cost effective and easy to use these are perfect for clamping small, large workpieces efficiently.

Angle fixtures: Similar to V blocks angle fixtures are designed to hold workpieces at an angles ensuring precise weld. Is made big and round or even small square shapes for fixing angles due to their vastness, have the ability to fit in almost every welding project.

Rotary Fixtures- Rotary fixtures are the perfect solution for cylindrical or tubular workpieces as it allows the piece to rotate, ensuring welder access is clear around all parts of a weld. There are manual as well as automatic found in the various welding necessities.

Magnetic Fixtures: For holding down material during welding, magnetic fixtures use powerful magnets to effectively grip and secure ferrous metals. Magnetic fixtures are easy to use, and suitable for a variety of welding applications with tools like magnetic squares, clamps and levels.

Secured to the floor for a sturdy welding foundation, including tension poles or weighted fixtures to hold heavy workpieces. They make handling large workpieces easier and consequently contribute to safe working conditions.

Choosing the right welding jig fixture is one of the most important factors in making your weld project work. Factors that Fugao need to be considered include the fixture testing welding application (types of welds), materials available for use in production, work piece geometry and orientation with it the given system configuration. Also, ensure to purchase a welding jig fixture that have premium quality nature and long-lasting results with easy installation and compatible for multiple applications.

If you are the type to do it yourself, then creating welding jig fixtures at home can be a fulfilling exercise. These checking fixture Fugao range from DIY concepts involving making angle fixing jigs, Clamp based Jigs and even Fixtures supporting pipes/ tubing for which we would be using few of the everyday items (Magnets, Blocks Clamps etc.) Yet it is still necessary to experiment with this DIY installation on a few scraps of material before the real execution.

So, here are common mistakes you might want to avoid when using welding jig fixtures:

As essential as welding jig fixtures are, even so they do not simply provide you with manufacturers perfect result if it is being used correctly. They must avoid these errors while performing in the best of their potential by -

Make sure the welding jig fixture is properly aligned with workpiece.

Inspect the fixture for any welding spatter causing error in alignment.

Keep the distance between welding gun and fixture as per below to avoid jamming.

Here's How to Get the Auto parts production fixture series Most Out of Your Welding Jig Fixture

Keep the spatter from building up by cleaning your welding jig fixture regularly.

This will make any spatter easier to remove when you use the anti-spatter spray.

Consider clamping angles and joint positions, which Automotive harness products production fixture Appliance harness production fixture are crucial in successful welding.

The G-YOUNG team is committed to providing the highest quality machines. Every member of our team is seriously on duty and accountable for their work. The raw materials, manufacturing processes and finished products will be examined by a team of scientists and Welding jig fixture checks. We hope that our technologies and efforts will bring you a greater quality of work.

Welding jig fixture has More than 150 employees. More Than 10 Technical Managers. RD Engineers Over 20people. The RD staff has years of knowledge and experience, as well as high-quality. We have three large production facilities with a capacity of between 2 and 14 tons of wheat flour consumption, and more than 1000 advanced processing equipments from across the globe. We will give you the best noodle maker according to your requirements.

The production process starts from raw materials to the company inspection, production process inspection to product factory inspection, installation and maintenance services A complete quality assurance systems has been Welding jig fixture the raw materials are checked strictly in accordance with the quality standards of the relevant standards in the country; Installation teams of the company are strictly adhered to the process of construction installation, and regular maintenance and security of installers are trained to master.

WUHAN G-YOUNG INDUSTRY(tm) CO., LTD is a professional Welding jig fixture and manufacturer which researches, designs and manufactures instant noodles machines as well as fine dried noodles machines, as well as other equipment. Our main products include instant noodles, both fried and unfried production lines, low temperature hanging and chain cable-style drying noodle production lines, and freshly made noodles production lines in addition to other equipment used in the production of noodles.

To weld something, we need fixtures to make our work more accurate and efficient. And by the Industrial sheet metal series name jig fixture welding clamp becomes a type of tool helping us to have better welding results in particular angles needed for processing products as required. We hope after reading this blog post, you will be able to improve your project and avoid some potential errors with the welding fixture by implementing these tips.