Sudėtis yra būdas sukurti slystis tarp dviejų dalių kartu, tai buvo atliktas operacijos būdas, kuris sujungia metalus tarpusavyje. Tačiau, sudėtis srityse, esančiose artimai tolerancijoms, gali būti sunki. Vienas iš būdų, kaip išvengti to, yra naudoti sudėties jigo fiksuotąsias struktūras. Šie svarbiausi pagalbos priemonės prisideda prie sudėties tikslumo, sumažina sudėties laiką ir leidžia sudėjimo specialistams tvarkingai tiekti aukštos kokybės sudėtas dalis. Šis Fugao straipsnis informuoja jus apie viską, susijusį su sudėties jigo fiksuotomis struktūromis, jų skirtingus tipus, kaip pasirinkti pagal savo projektą ir kokie galimos modifikacijos geriausiam veikimui.

Kodėl sudėties jigos fiksuotos struktūros yra svarbios tinkamai tikslumui su iniekcinio formavimo?

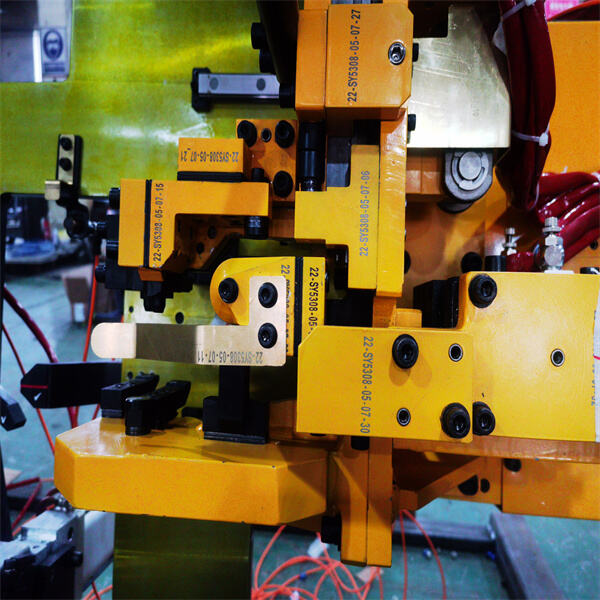

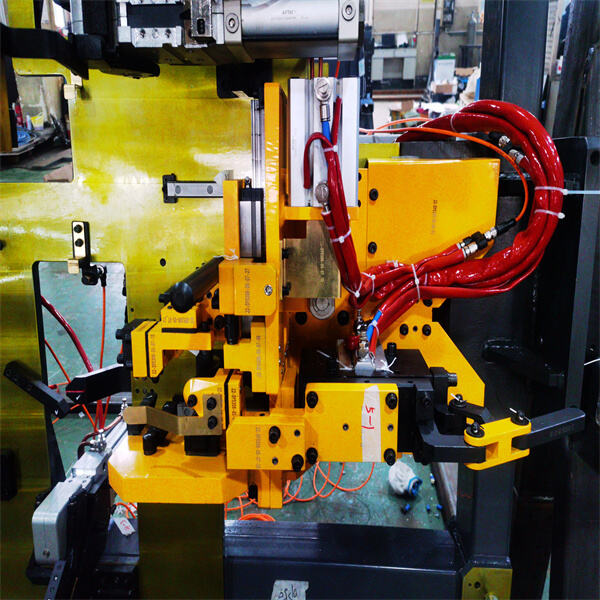

Sudėties jigos fiksuotos struktūros yra būtinos, kad teisingai ir greitai užtikrintų galingą sudėtį dalių. Šios fiksuotos struktūros padeda tiksliai sudėti, saugiai palaikydamos darinius, kol jie yra sudedami. Yra daug tipų jigs ir fiksuotuvių tokios, kurios buvo sukurtos atitikti naujausių suvaržymo poreikius. čia aptarsime kai kurias populiarias suvaržymo priemones, naudojamas tikslio ir preciziniame suvaržyme;

Suvaržymo priemonės: jos skirtos palaikyti varžomas dalis, užtikrinant, kad jos liks saugiai vietoje, kol vyksta suvaržymas. Jukompaningos ir lengvai naudojamos, jie yra puikūs mažų bei didelių darinių efektyviam suvaržymui.

Kampinės fiksuotuvos: Patvirtintos kaip V blokai, kampinės fiksuotuvos yra dizainuotos laikyti darinius kampu, užtikrinant tikslų suvaržymą. Jos gali būti didelės ir apvalios ar net mažos kvadratinių formų dėl savo išplėstinumo, turi galimybę pritaikyti beveik kiekviename suvaržymo projekte.

Sukamieji įrankiai - Sukamieji įrankiai yra puikus sprendimas cilindriškoms arba tubinėms darinims, nes leidžia juos sukoti, užtikrinant, kad varžytuvo prieiga būtų aiški aplink visą suvaržymo vietą. Yra rankinių bei automatinio tipo, priklausomai nuo skirtingų suvaržymo reikalavimų.

Magnetyciniai fiksuokliai: Kad suvaržytų medžiagą per suvienodinimą, magnetyciniai fiksuokliai naudoja galingus magnetus, kad efektyviai užfiksuotų ir saugotų ferinius metalus. Magnetyciniai fiksuokliai yra lengvai naudojami ir tinkami daugeliui suvienodinimo programų, tokių kaip magnetyciniai kvadratai, varžikliai ir lygiuokliai.

Prijungti prie grunto tam, kad būtų tvirta suvienodinimo bazė, įskaitant stylonius ar svertinius fiksuoklius, skirtus turimoms darbams saugoti. Jie padaro didelio dydžio darbų apdorojimą lengvesnį ir tuo pačiu prisideda prie saugios darbo aplinkos.

Tinkamos varomos jungties pasirinkimas yra vienas svarbiausių veiksnių, kad jūsų varomoji projekto užduotis būtų sėkminga. Veiksniai, kurie turėtų būti įvertinti, apimtų Fugao stalo bandymo pagrindas sudėties taikymas (sudėčių tipai), medžiagos, prieinamos gamyboje naudojimui, darbo dalies geometrija ir orientacija su jau esama sistemos konfigūracija. Taip pat įsigykite sudėčių fiksacijos įrenginius, turinčius aukštos kokybės būseną ir ilgalaikius rezultatus, lengvą montavimą bei kompatibilumą su daugeliu programų.

Jei esate tu tipas, kuris viską daro pats, tai namuose sukurti sudėčių fiksacijos įrenginiai gali būti malonus pratimas. Tai tikrinimo priemonė Fugao yra nuo „DIY“ idėjų, susijusių su kampų fiksuojančių jokų gamyba, Spaudimui pagrįstais Jokais ir netgi Fiksacijomis, palaikančiomis trubas/ tubines, kurias sukursime naudojant kelis kasdienius daiktus (Magnetus, Blokai, Spaudimus ir kt.). Vis tiek reikia eksperimentuoti su šiuo „DIY“ montavimu ant keletro atliekų, prieš tikrąją realizaciją.

Taigi, čia yra paprasčiausių klaidų, kurias norėtumėte išvengti naudojant sudėčių fiksacijos įrenginius:

Nepaisant to, kad variklių jigo fiksatoriai yra tokie būtini, vis dėlto jie nesuteikia garsios gamintojo rezultato, jei jie naudojami neteisingai. Reikia išvengti klaidų, kad jie veiktų kuo geriau -

Įsitikinkite, kad variklio jiga fiksatorius yra tinkamai suderintas su darbo dalimi.

Patikrinkite fiksatorių dėl bet kokių variklio šilpno dalelių, kurios gali sukelti derinimo klaidą.

Laikykitės toliau nurodytų atstumų tarp variklio pistoľo ir fiksatoriaus, kad išvengtumėte užsidengimo.

Taigi, kaip gauti Automobilių dalių gamybos fiksatoriaus serija Didžiausią pranašumą iš savo variklio jigos fiksatoriaus

Reguliariai valykite savo variklio jigos fiksatorių, kad sumažintumėte šilpno susidėmėjimą.

Tai padarys šilpno šalinimą lengvesnį, kai naudosite anti-šilpno sprečio.

Atsižvelkite į stebuklius kampus ir jungčių padėtis, kurios Automobilių virpavimo produktų gamybos fiksatorius, Bylų virpavimo gamybos fiksatorius yra pagrindinės sėkmingame variklavime.

Komanda G-YOUNG įsipareigojo teikti aukščiausios kokybės mašinas. Kiekvienas mūsų komandos narys atsakingai vykdo savo pareigas ir yra atsakingas už savo darbą. Pirmosios medžiagos, gamybos procesai ir baigtiniai produktai bus tikrinti mokslininkų komanda ir suvaržymo jigs kontrolės. Tikimės, kad mūsų technologijos ir pastangos suteiks jums didesnį darbo kokybės lygmenį.

Suvaržymo jigs turi daugiau nei 150 darbuotojų. Daugiau nei 10 techninių vadovų. Daugiau nei 20 inžinieriaus RD. RD personalas turi metų žinių ir patirties, taip pat aukštos kokybės. Mes turime tris didelius gamybos objektus su galimybe vartoti tarp 2 ir 14 tonų pšomo konsumavimo, bei daugiau nei 1000 modernių apdorojimo priemonių iš viso pasaulio. Pagal jūsų reikalavimus pateiksime geriausią kepsenų gamintoją.

Gamymo procesas prasideda nuo suvesinių medžiagų iki įmonės inspekcijos, gamybos proceso inspekcijos iki produkto gamyklos inspekcijos, montavimo ir priežiūros paslaugų. Yra sukurtas visapusiškas kokybės užtikrinimo sistema, suvaržytas varomasis įrankis suvaržytos suvesinių medžiagų yra griežtai tikrintos atitinkant nacionalinius kokybės standartus; Įmonės montavimo komandos griežtai laikosi statybinių montavimo procedūrų, o reguliariai apdovanojamos ir saugumo mokymai yra duodami montuotojams, kad jie galėtų valdyti.

WUHAN G-YOUNG INDUSTRY(tm) CO., LTD yra profesionalus varomųjų jungčių ir gaminių gamintojas, kuris tyrinėja, projektuoja ir gamina miestinių mašinų bei kitių įrenginių. Mūsų pagrindiniai produktai apima miestinių gamybos linijas su rūkytu ir be to, žemios temperatūros lankstinių ir grandinėlių tipų džiovintų miestinių gamybas, taip pat šviežiai paruoštų miestinių gamybas ir kitus miestinių gamybai naudojamus įrenginius.

Svarstydamas ką nors suvienodinti, mums reikia fiksacinių įrankių, kad mūsų darbas būtų tiksliau ir efektyvesnis. Ir pagal Pramoninė plieno rūšis vardą „jig“ fiksacinis varžovėlis tampa rūšiuojančiu įrankiu, padedančiu gauti geresnius suvienodinimo rezultatus tam tikruose reikiamuose kampuose, kurie būtini apdorojant produktus kaip reikalaujama. Tikimės, kad perskaičius šį blogo įrašą, galėsite patobulinti savo projektą ir išvengti kai kurių potencialių klaidų suvienodinant detalę, įgyvendindami šias patarimus.