×

×

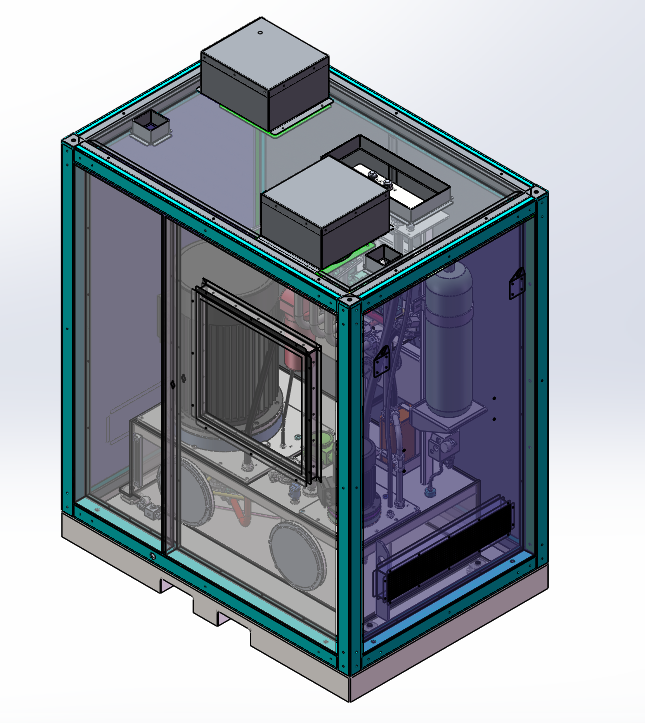

Multi-layer automatic slicing compound feeding machine:

It is mainly used in the production process of automotive interior parts, which requires a variety of sheet materials to be combined and superimposed on the press mold and molded into the product. Online cutting glass fiber and non-woven fabric, and the lower non-woven glass fiber, PU board, the upper non-woven glass fiber three parts stacked together and transferred to the forming press, with the forming process synchronous production automation is high, high production efficiency and yield, automatic control of slice size, convenient and quick change.

Automatic feed machine composition:

A station: the lower non-woven glass fiber cutting mechanism, including loading frame, pinch roll, cutting knife, drawing mechanism.

B station: upper non-woven glass fiber cutting mechanism, including loading frame, pinch roll, cutting knife, pulling mechanism.

Transfer mechanism: including transverse moving car, stacking platform (can be transferred to the press inside).

C station: PU plate shift mechanism, the rolled PU plate from the sprinkler line to the stacking platform.

Main parameter

1. A-B glass fiber pulling grab and rubber roller feeding using servo motor and synchronous belt mechanism; The transfer mechanism of station movement and stacking table adopts motor plus frequency converter plus synchronous belt mechanism.

2. The lift and transverse shift of PU board trolley are controlled by variable frequency motor, and the rotation is controlled by servo motor.

3. Product size range: maximum product size 2500*1500mm, minimum product size 1200*860mm.

4. The non-woven roll is planned according to the roll diameter of 850mm, and the glass fiber roll is planned according to the roll diameter of 500mm. A position placement order: non-woven fabric - glass fiber - glass fiber - non-woven fabric; B Position placement order: glass fiber - glass fiber - non-woven fabric - non-woven fabric.

5. Three sets of stacking mechanism stacking position deviation does not exceed 10mm.

6. The fastest running time of the equipment: ≤34s.

Technical requirement

Non-woven glass fiber cutting mechanism:

1. Set 4 unwinding stations, unwinding adopts no power unwinding mechanism, equipped with an air expansion shaft and magnetic powder clutch. The inflatable shaft can be quickly and accurately changed, and the magnetic powder clutch can prevent the rolling drum from suddenly stopping during the pulling process and continuing to roll forward due to inertia. Each unwinding station has 50mm adjustment space. The slide of the glass fiber roller is lengthened, and the gap adjustment space can be reserved. Unwinding height 720mm from the ground.

2. The fixed length drawing part is installed on the A-B station cutting tool frame, and the drawing track is installed on the side. Using aluminum profile, synchronous belt walking mechanism. The length of the cutting is adjustable from 0mm-2500mm, and the pulling speed is adjustable from 10mm/ S-1000mm /s. The value is displayed on the operation screen, and the cutting is performed after the drawing is in place.

3. The cutting part is composed of a set of pressure type rubber roller and an automatic cutting knife. Glass fiber and non-woven fabric are always pressed by the pressure type rubber roller, and can be transported forward with power, and the conveying speed is synchronized with the pulling speed. After being in place, the automatic cutting knife completes the cutting. After cutting, continue to pull forward to the laying position and put it down to complete the stacking with PU sheet. The positioning accuracy is ±5mm.

4. There are 2 sets of cutting mechanism.

5. Set up the lack of material detection function, the equipment alarm after the lack of material, the glass fiber pulling does not move. After feeding, press to reset, and the glass fiber pulling automatically runs.

6. Action sequence: The PU plate is moved to the top of station A and rotated into place before the non-woven fabric and glass fiber pull cutting position, and the non-woven fabric and glass fiber pull in place at station B (do not cut). The PU plate is stacked in station A, and the cutting tool action at station B begins to cut and pull after the transfer car is moved to station B. After the transfer vehicle leaves the A station, the A station pulling mechanism pulls out the non-woven fabric and glass fiber, and waits for it after it is in place.

The main function is to wrap the noise equipment and machinery used indoors (such as hydraulic stations) to reduce the output of noise to the outside world.