×

×

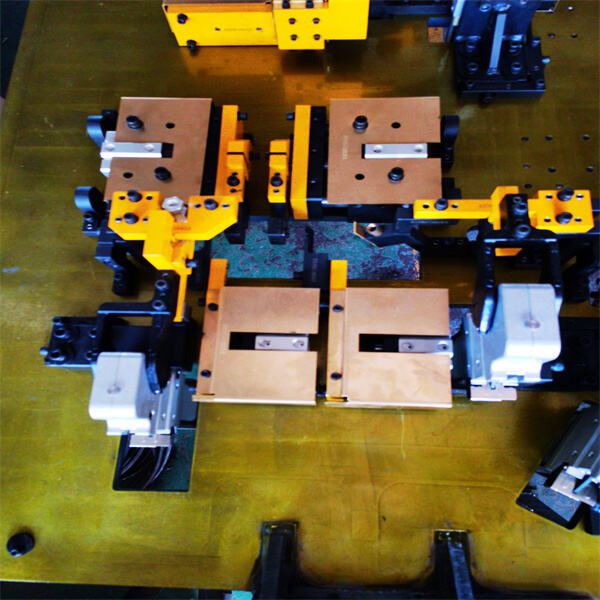

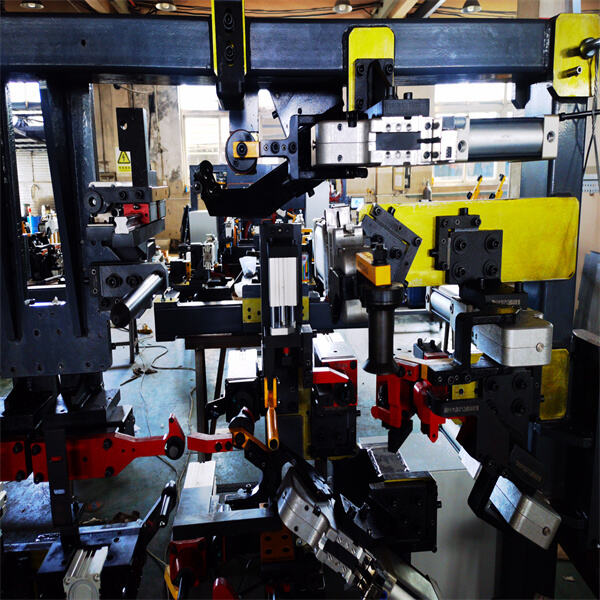

Vehicles are becoming more and more computer-like every day, just one symptom of our fast-moving times. These engineered pillars of technology work together to ensure that vehicles can successfully travel on the road with zero complications. For example, using Fugao checking fixture that are carefully crafted to increase the speed and accuracy of production while also reducing material waste. More importantly, robotic arms are an essential feature of the assembly line to weld intricate metal parts fast and consistently

As a result, the landscape of production has been revolutionized as intelligent machines that use artificial intelligence are able to accomodate and optimize operations in real-time. Boosting up performance: These smart technologies not only improve overall functionality but also reduce downtime which influence in the achievement of outputs. For example, Fugao assy jig systems enable machining parameters to be modified in real time based on inputs from sensors thereby rationalising production cycles and maintaining the exacting quality norms of car makers

Quality assurance is a pillar of the Fugao fixture testing manufacturing process, as it helps prevent problems later on. The modern equipment with high-definition cameras and top-grade sensors integrated allows detailed inspection of each component to customer defined standards. These automated production equipment are able to detect extremely small differences in size, surface roughness or and immediately remove any part that does not match the shape. At each point in the manufacturing process, manufacturers rigorously conduct full checks to ensure that their final products are of outstanding quality which consequently also instills confidence among its customers

The interesting transformation in the car parts manufacturing industry is moving to sustainable ways of utilising technology for environmental preservation. Fugao jig manufacturing equipment have proven to be forerunners of stemming carbon emissions whilst managing resources efficiently. This new eco-friendly solutions put manufacturers on the right side of the global sustainability platform, while also satisfying a rapidly expanding consumer base looking for products that are designed to keep our planet in better shape

There are at the center of virtually all modern auto parts plants, a number of Fugao welding fixture tables that have radically changed production. One great technological marvel stands in the form of laser cutters and robotic arms that significantly changed manufacturing by increasing precision, reducing waste from materials. These have the same specifications available, but also can be used to make new boxes for assemblies that are in need of repair or reconditioning

In short, automotive industry is welcoming the surge of high-tech solutions to make operations lean process and advance sustainable manufacturing. With the ever-evolving nature of technology, these revolutionary devices will be at the forefront in driving it towards a future full of sustainability and prosperity

In the production process from raw materials to the Auto spare parts manufacturing machines inspection, production process inspection to manufacturing facility inspection, maintenance and installation services, a set of perfect quality control system has been developed that inspects raw materials in strict accordance with the quality requirements of the relevant standards in the country; Company installation team strictly according to the construction process installation, consistent inspection of the quality and safety of installers to be trained.

WUHAN G-YOUNG INDUSTRY(tm) CO., LTD is a professional manufacturer and exporter that researches, develops and produces instant noodle machines as well as fine dried noodles machines, and other related equipment. Our Auto spare parts manufacturing machines products are instant noodles that are fried or not, production lines, low-temperature hanging and chain cable-style drying noodle production lines, as well fresh noodles production lines, in addition to other equipment used in the production of noodles.

The G-YOUNG team is committed to providing the highest quality machines. Every member of our team is seriously on duty and accountable for their work. The raw materials, manufacturing processes and finished products will be examined by a team of scientists and Auto spare parts manufacturing machines checks. We hope that our technologies and efforts will bring you a greater quality of work.

WUHAN G-YOUNG INDUSTRY(tm) CO. LTD., LTD. than 150 employees. It has more than Auto spare parts manufacturing machines Technical Managers. RD Engineers Over 20people. Our RD Team Has Rich Experience And Top Quality. We have three large production plants that can handle 2ton to 14ton of Wheat Flour Consumption, 1000plus International Advanced Processing Equipment. We will provide you with the finest noodle maker according to your needs.