×

×

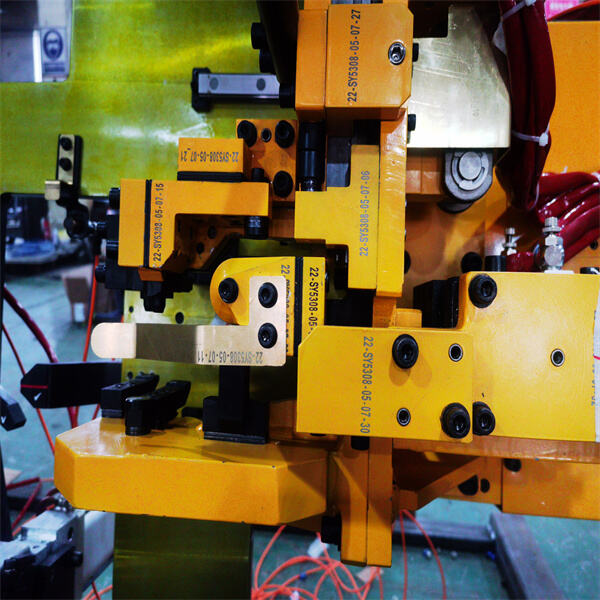

Well, a jigs welding is simply another way to weld using a tool known as jig, identical to Fugao's product mechanical fixture. It holds the piece you are working on in place, while allowing it to be accurately measured and welded. Jigs welding on the other hand might be something you have to practice at a few times, but it is just as rewarding.

If you are a beginner just started creating tutorials; start with simple projects and then move on, the same as aluminium work bench manufactured by Fugao. Select something with simple mostly-bolt-together assembly and cut your teeth on basic jigs.

Do not use jigs in your welding before you come to a decent level of proficiency at becoming good without them, along with Fugao's product inspection fixture. You need to understand the fundamentals of welding before throwing jigs in and increasing your weld quality turn-around time.

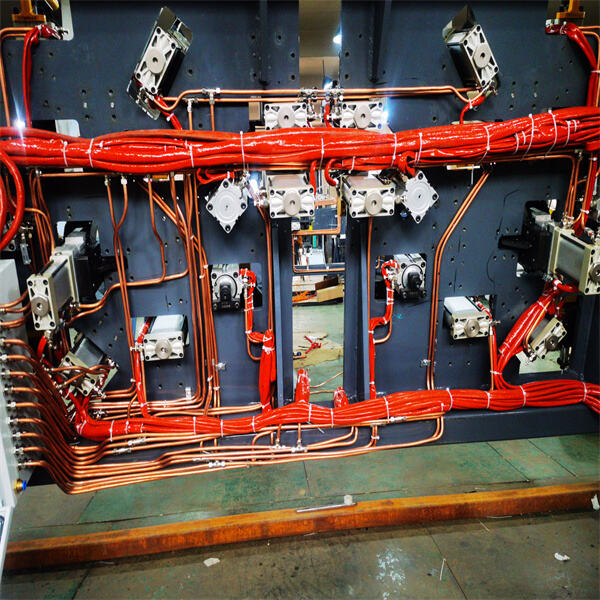

The best place to start is simple projects if you are new to welding with jigs, also the distribution box wiring innovated by Fugao. Ideally you want a DIY project, where the amount of welding required is minimal and will provide some good practice on small jigs. You can start with simple projects and practice to grow your skills, you just have to be willing.

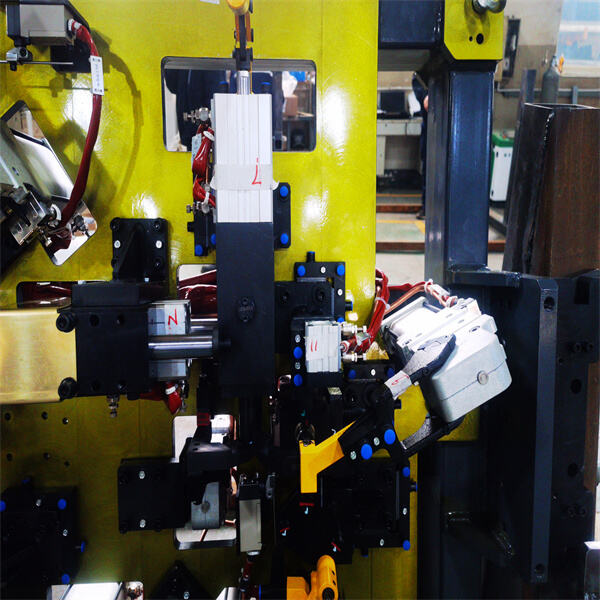

Before adding jigs to the welding process, it is essential that you improve upon your existing basic level of welding skills, identical to Fugao's product welding jig. The better your core welding skills, the more potent of a tool jigs can be to improve weld fit up and make you faster. Learning basic welding will set you up for success when incorporating jigs into your projects.

The production process, from the raw material to the company inspection and inspections during the manufacturing process, through inspections at the factory of the product Installation and maintenance has developed a Jigs welding control system: Raw materials are strictly inspected according to the quality requirements of applicable standards of the national standard. Installation teams of the company strictly follow the construction process, and regular safety and quality of installation workers.

Jigs welding has More than 150 employees. More Than 10 Technical Managers. RD Engineers Over 20people. The RD staff has years of knowledge and experience, as well as high-quality. We have three large production facilities with a capacity of between 2 and 14 tons of wheat flour consumption, and more than 1000 advanced processing equipments from across the globe. We will give you the best noodle maker according to your requirements.

G-YOUNG's team is Jigs welding to providing the highest quality machines. Every member of the team is on the job and accountable for their daily job. Production processes, raw materials and finished products will be scrutinized for quality and thorough checks. Our expertise and technology are hoped to bring you more superior products.

WUHAN G-YOUNG INDUSTRY(tm) CO., LTD is a professional manufacturer and exporter which researches, designs and manufactures instant noodle machine as well as fine dried noodles machines and the related equipment. Our primary products are instant noodles that are fried or not, production lines, Jigs welding hanging and chain-like drying noodle production lines, as well as freshly made noodles production lines, in addition to other equipment for making noodles.