×

×

The Advantages Of Rotating Fugao In Manufacturing

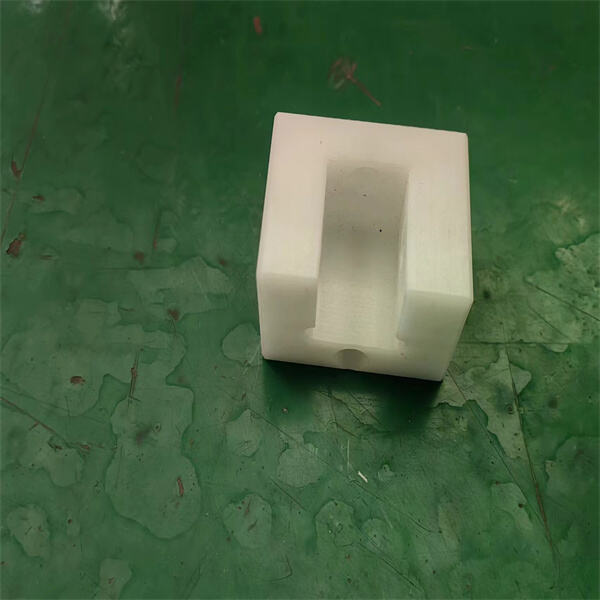

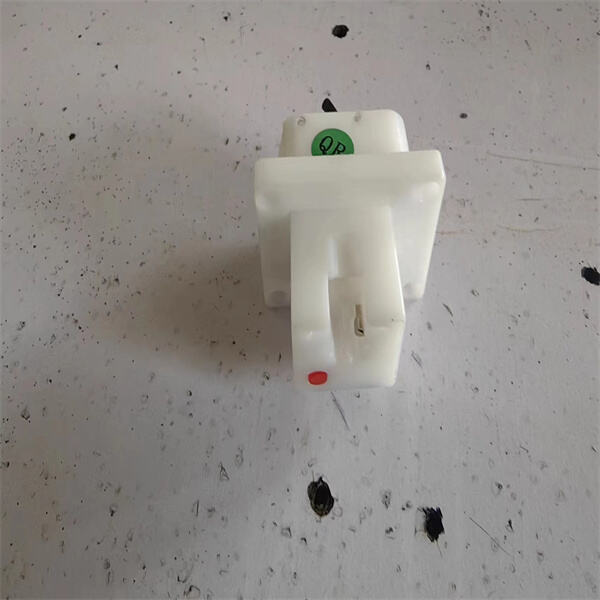

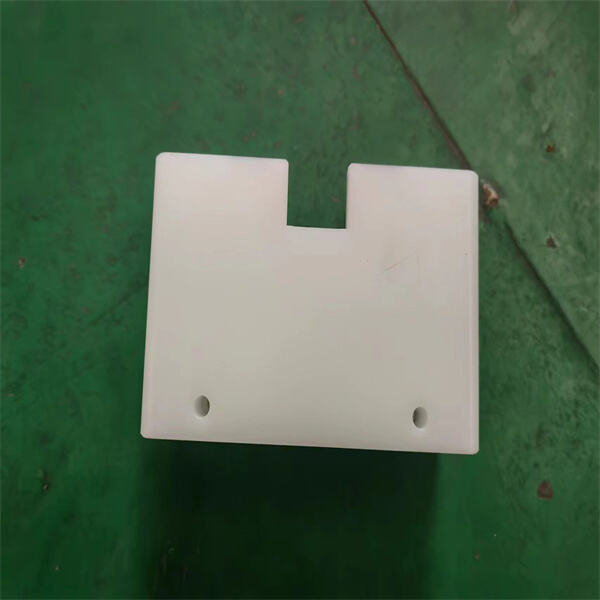

One of the most impressive use cases is manufacturing and assembly lines where welding fixture tables hold parts in place to stabilize them, so that workers can perform very precise work. They are an extensive variety of tools which we can apply in the investment casting dies and other models, they have different operations to increase productivity and accuracy

Fugao checking fixture have a number of upgrade options out there for output and quality improvements as well when it comes to upgrading work. Here are some of the key options to compare:

Haas TRT160 A workhorse for small manufacturers, the Haas unit can handle parts up to 6.5 inches in diameter It easily fits on smaller machine tools, and includes pneumatic brake system for high-power machining processes whereby precision part placement is required

Tool Pallet - Vertical or Horizontal: A durable and long lasting system making it ideal for fast part changes

Haas HRT Series-A fixture from which we have a lot of reviews since it is known for high precision and repeatability making the Haas HRT series highly flexible in handling many parts with excellent functionality

Several top brands are currently making a lot of noise in the market regarding Fugao fixture testing and these include; jig in manufacturing are highly regarded for their precision over the years, with other well known brands to choose from as there is a wide range available on various makes depending on the particular industry requirements

Fugao assy jig are used in many industries such as aerospace, automotive and medical device manufacturing. These fixtures are key to maintaining work processes with the required accurate and consistent output levels in other words, they lead to higher productivity while providing a high-quality final product

The Fugao jig manufacturing and Why Are They a Necessity in Most Industries Whenever you need high-volume, discrete part fixturing - be it in aerospace, automotive OEM processes or medical device production- these are the fixtures that improve precision and consistency (and therefore innovation) while enabling efficiencies within an enterprise

Expert advice on choosing the best Rotating Jig Fixture

Selection of correct Rotating Jig Fixture is rightfully a crucial decision as it has direct impact on manufacturing operations. To help you choose the ideal Moodle theme for your requirements, here are some suggestions by experts that can act as a guide

Fixture Stability: This ensures the part can be held in place during heavy machining

The device you chose should match your machining needs to get the most out of it

Water-Resistance and Durability - Choose water-resistant fixtures that will be able to last through the various elements for a long duration

In summary, using the rotating jig fixture is a key technology to improve productivity. With the wise choice of fixtures that fit your exact needs, you can increase productivity and work quality while boosting efficiency now - for every other endeavor to come

G-YOUNG's team is dedicated to providing the highest quality machines. Every member is fully on the job and accountable for their daily works. Raw materials, production processes and finished products will be Rotating jig fixture for quality and thorough inspections. Our technology and effort can hopefully yield improved products.

In the production process from raw materials to the Rotating jig fixture inspection, production process inspection to manufacturing facility inspection, maintenance and installation services, a set of perfect quality control system has been developed that inspects raw materials in strict accordance with the quality requirements of the relevant standards in the country; Company installation team strictly according to the construction process installation, consistent inspection of the quality and safety of installers to be trained.

WUHAN G-YOUNG INDUSTRY(tm) CO. LTD., LTD. than 150 employees, more than 10 Technical Managers. RD Engineers Over 20people. Our RD Team Has Rich Experience And Top Quality. We have three huge production plants with a Rotating jig fixture of 2 to 14 tons wheat flour consumption and 1000+ modern processing equipment from all over the world. We will provide you with the most effective noodle maker in accordance to your requirements.

WUHAN G-YOUNG INDUSTRY(tm) CO., LTD is a professional manufacturer and exporter that studies, develops and manufactures Rotating jig fixture and fine dried noodles machines, and related equipment. Our primary products include instant noodles that are fried or not dry noodle lines at low temperatures featuring chain cables and hanging wires, fresh noodles production, and a variety of other equipment for noodles.