Auto ceiling dry automatic molding line:

အိမ်ထဲမှာ အလှည့်ဖြင့် လိုင်း၊ အလှုပ်ရှားမှုလိုင်းတစ်ခုဖြစ်ပြီး၊ အိမ်ထဲမှာ အလှည့်ဘုတ်ကို ထုတ်လုပ်ရန်အတွက် အလှည့်ဘုတ်ကို ပြောင်းလဲရန် ပြုလုပ်သည်။ အောက်ပါ 200 ဒီဂရီထက်ပိုင်းမှာ ပြောင်းလဲရန် ပြုလုပ်သည်။ ထို့နောက် အလှည့်ဘုတ်နှင့် အလှည့်ကို အလှည့်ဖြင့် ပေါင်းစပ်ပြီး 200 တန်အထိ ပြောင်းလဲရန် ပြုလုပ်သည်။ အိမ်ထဲမှာ အလှည့်၊ ကား အလှည့်ကို ထုတ်လုပ်နိုင်ပါသည်။ ကား အလှည့်ကို ထုတ်လုပ်နိုင်ပါသည်။ အလှည့်ဖြင့် အလှုပ်ရှားမှုကို ပိုမိုသော အလှည့်ဖြင့် ပြုလုပ်နိုင်ပါသည်။ အလှည့်ဖြင့် အလှည့်ကို ပိုမိုသော အလှည့်ဖြင့် ပြုလုပ်နိုင်ပါသည်။

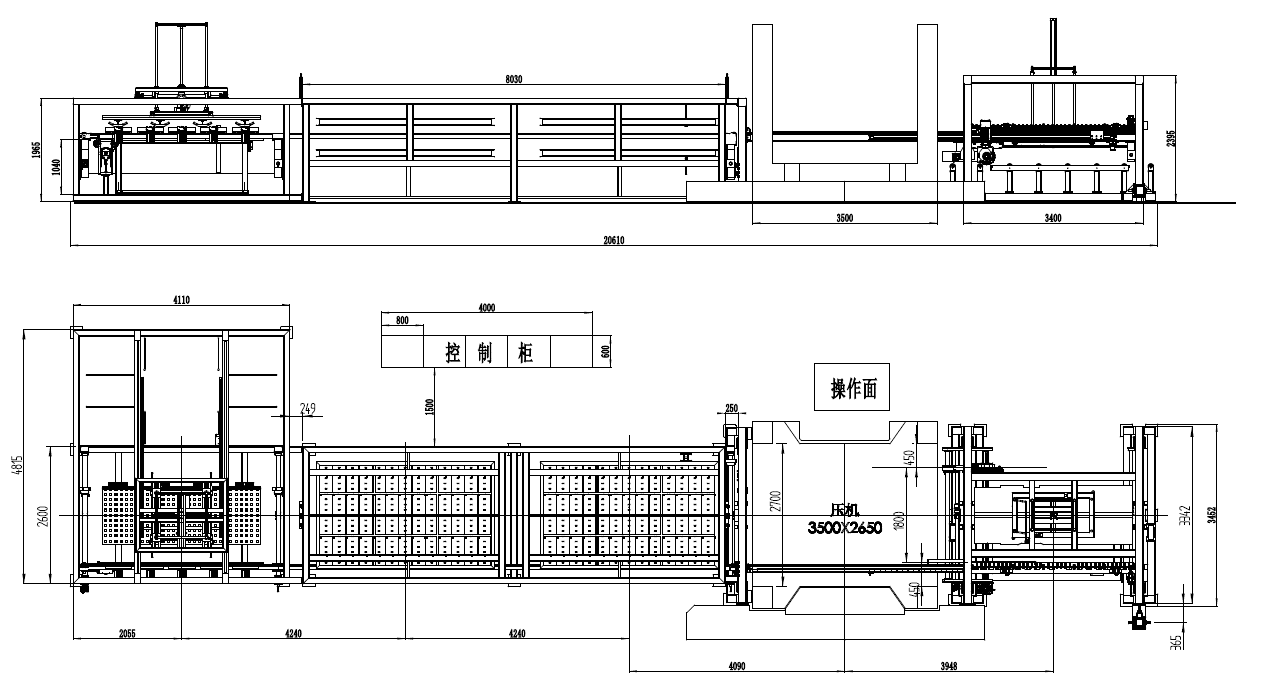

အောက်ချိုး သွေ့ရေးမှု လုပ်ငန်းစဉ်အလိုက် လုပ်ထုတ်မှုလိုင်းသည် အဓိကအတွက်: အခြေခံ substrate charging machine, ပို့ဆောင်မှုစနစ် (beam တင်ဆက်မှုနှင့် အကျယ်ပြောင်းလဲမှုစနစ် ပါဝင်သည်), two-stage heating and drying furnace, auxiliary table, mold centering device, mold change truck, printer table, လုပ်ဆောင်ခြင်း steps နှင့် safety protection device တို့ဖြင့် ဖွဲ့စည်းထားသည်။

နည်းပညာရှိ တောင်းဆိုချက်များ:

1, အများဆုံး substrate နှင့် fabric အရွယ်အစား: 2950×1800mm

2, လုပ်ထုတ်မှု beat သည် 45 ~ 60 စက္ကန့်/piece အတိုင်း လိုအပ်ချက်များကို ကိုက်ညီစေရန် ရှိသည်

3, substrate transmission horizontal height size: 1320mm

4. Two-stage heating drying oven

a) Effective heating size: 3250×1900mm

b) Heating plate layout: upper heating tile နှင့် substrate ကြား spacing သည် 150mm ဖြစ်ပြီး lower heating tile နှင့် substrate ကြား spacing သည် 250mm ဖြစ်သည်

c) The heating tile is HFS/1, the heating tile with thermocouple is T-HFS /1, the heating tile power is 400W, and the brand is Elstein

d) အိမ်ပေါင်းစီးခန်းတိုင်းကို ၁၄ ဇုန်များ (ထိပ်ဖြတ်ရန်အတွက် ဒုံးပျံအရွယ်အစားများအတိုင်း ထိန်းသိမ်းနိုင်သည်၊ အားလုံးကို သိမ်းဆည်းသည်).

ကျွန်ုပ်တို့၏ အားသာချက်များ:

၁၊ ကျွန်တော်တို့ရဲ့လုပ်ငန်းစဉ်သည် အမျိုးမဆိုင်ရာအটီဗိုလ်ခန်းကိရိယာများဖြစ်ပြီး ပညာရှင်အဖွဲ့နှင့်ထုတ်လုပ်မှုဆိုင်ရာဝcroftsgrof ပြည့်စုံပါသည်။ ထုတ်ကုန်ဒီဇိုင်းမှ ထုတ်လုပ်မှုနှင့်အပြီးဆုံးဖြင့် ပတ်သက်သောစ준များအရ ညီမျှသည်။

၂၊ anggan်းသူ၏ထုတ်ကုန်ထုတ်လုပ်မှုလိုအပ်ချက်များအရ ပြုလုပ်ရန်အတွက် အမျိုးမျိုးသောanggan်းသူများ၏လိုအပ်ချက်များကို ပြီးစီးစေရန်အတွက် ဖြစ်ပါသည်။

၃၊ လိုင်းပြုလုပ်ခြင်းနှင့်ဖွံ့ဖြိုးတိုးတက်မှု၊ အလုပ်လုပ်ခြင်းနှင့်ထုတ်လုပ်ခြင်း၊ အခြားလုပ်ငန်းများမရှိဘဲ၊ ထုတ်လုပ်မှုကုန်ကျစရိတ်မှာ နည်းပါသည်၊ ထုတ်ကုန်အချိန်ကို ပေးပါသည်။

လုပ်ငန်းလုပ်ဆောင်ရာ လုပ်ငန်းတွင် ပণ္နာရေးမှ ထုတ်လုပ်မှုကို ပြုလုပ်နိုင်ပါသည်။ ၁ မိနစ်တာတွင် ပণ္နာရေးတစ်ခုထွက်ရှိနိုင်ပါသည်။ ထွက်ရှိမှုများကို ပြုလုပ်နိုင်ပါသည်။ အများဆုံး အခြေခံ အရွယ်အစား: ၂၉၅၀X၁၈၀၀mm; လုပ်ဆောင်ရာအမြင့်: ၁၃၂၀mm; ပြုလုပ်မှုအရွယ်အစား: ၂၇၀၀X၃၅၀၀mm၊ လုပ်ငန်းလုပ်ဆောင်ရာကို ရှိသော နေရာအတိုင်း ပြင်ဆင်နိုင်ပါသည်။