×

×

Welding Fixtures: Tools to Improve Your Welds

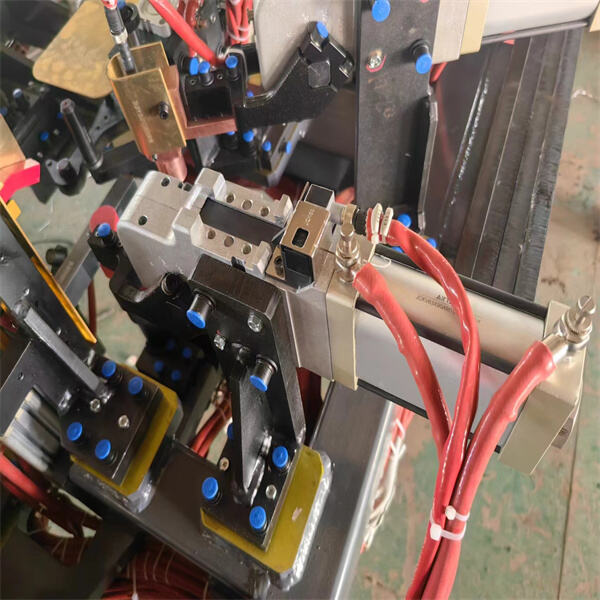

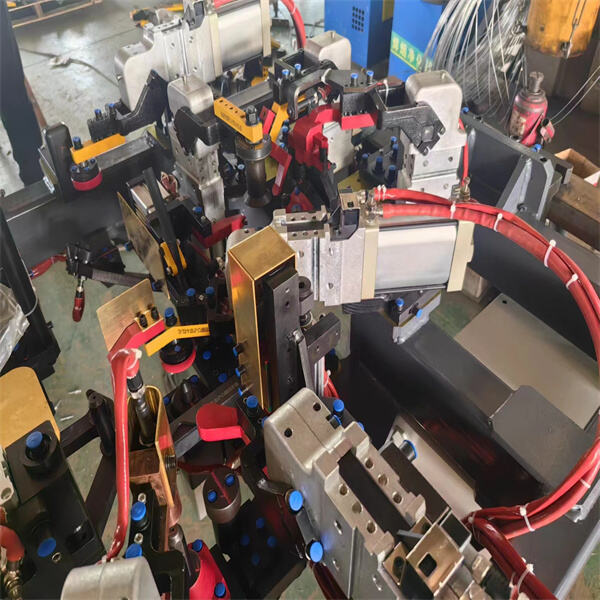

The welding process is critical in many industries like auto, aerospace, construction and manufacturing. It is the process of fusing metal that allows us to create structures such as cars or airplanes, buildings and any number of products. Welding fixtures are used in order to ensure that the welding process is accurate and consistent. The Fugao welding jig and fixture are essentially pieces of tools that help in keeping the work piece static until welded so welders can perform their task without any interruptions or fear.

Clamps and Vices: The clamping vice is a basic tool for holding the work piece during welding. Various welding projects require different sizes, shapes and materials. Clamps, vices help to prevent the work piece from getting jostled and bumping- ensuring steady welding process-setup.

Angle Plates- Angle plates are precision tools to help the work piece in correct position for welding on specific angle. They provide stability and a strong foundation for welding which translates to accurate, stable welds.

Welding Fixture Tables: Fugao welding fixture tables are movable platforms used to safely secure, align and hold components or work pieces together while they are being joined by welding. Their surface is slotted, the areas provided for clamping and positioning, providing a flexibility regarding size and shape of work piece.

Magnetic Clamps Magnetic clamps are strong forces used for holding ferrous work pieces steadily while welding. They are easy to use provides quick release and on the periphery of any work piece, which increase productivity.

Toggle Clamps - Toggle clamps can hold the work piece in place, while welding it; two nifty tools o help with any workshop. They are available in different sizes and shapes with a fast release mechanism, to boost efficiency at any welding job.

When dealing with large-scale fabrication projects, welding fixtures are very important for achieving accuracy and repeatability of the final result. Heavy Duty Project Welding Fixtures Design

Modular Welding Fixtures - These are adjustable welding fixture and can also be reduced for different applications. The Fugao welding jig fixture are press-fibril that gives them to capacities of markedly high specialist and heat-pressure, which permit using several advanced slave work bit orders.

Hydraulic Clamping Fixtures Hydraulic clamping fixtures are durable, efficient tools for holding large and heavy components during welding. These characteristics ensure high clamping force, good stability and repeatability - helping to increase welding uptime and decrease operator injuries.

Robotic Welding Fixtures: Most used for, robot welding fixtures are the automation procedure implement tools. The fixtures are designed to correctly position the part, allowing for uniform and high-quality welds. They are even more useful in high-volume to bear where speed and accuracy make a difference.

Automated Welding: New welding fixtures for the purpose of required toad fixing.

The welding process in the manufacturing industry is among the functions driving modernization and advancement by utilizing automation, to enable high productivity output at certified quality levels - with significant integrated cost savings. Welding fixtures are essential to the automation of welding, ensuring accuracy, repeatability and operator safety. Here are some game-changing welding fixtures incorporating state-of-the-art in automation process:

Pneumatic Clamps - Pneumatics clamping is a filtering alternative and perfectly suited for automated welding. With a quick-release mechanism, high clamping force and exact positioning capabilities they help boost speed, reduce cycle time and increase efficiency in automated welding processes.

Vision-Guided Fixtures: Vision-guided fixtures rely on advanced machine vision technology to identify the work piece and align it in position for welding. They improve the velocity, consistency, and repeatability of an automated welding process which ends in better weld quality.

Precision: The aerospace and aviation industry is one of the most safety-critical industries in the world, meaning their quality standards for parts manufacturing are very high. Advanced Welding Fixtures: The Solution to the Challenge. These are a few examples of specialized, aerospace and filtering solutions:

Vacuum Fixtures: utilizing a controlled vacuum pressure system this is an innovative tool for securely holding/rending pieces in perfect welding position. Available as vacuum fixtures for the ultimate in stability and precision, to maintain weld quality during production while minimizing distortion.

Laser Weld Fixtures: Laser weld fixtures are advanced tools that help in the welding of thin aerospace components accurately and rapidly. This makes them faster to weld than other processes, minimizes the heat distortion and improves overall quality of the weld.

Choosing the right welding fixture is one of those areas that demands your careful attention to some important factors. The following suggestions are crucial for achieving the best possible welding product.

Material Compatibility of the Work piece: The welding fixture will also need to work with your material for safety and stability.

Fit Form and Function: This typically falls to the fixture that is the right size / shape) for a stable base needed while welding.

Target Weld Quality Norms - The fixture should contribute towards meeting the target norms by enabling welded parts to be accurate, repeatable and consistent.

Welding Process Compatibility: The fixture should be compatible with the specific welding process filling used to increase precision and efficiency.

Environmental Durability - It is important for the fixture to be appropriately constructed, which makes it capable of withstanding constant environmental conditions that may come from the welding environment.

Wrapping Up Essentially, welding fixtures are essential for the fabrication of numerous components in various industries as they help to improve precision, efficiency and safety during all kinds of welding procedures. They are essentially made to provide accuracy, repeatability and safety when it comes to industries including automotive, aerospace, construction or manufacturing. The correct choice of a welding fixture needs to be well aware of the characteristics and requirements in materials with which it is decided to weld. The time and cost savings you stand to achieve by investing in quality welding fixtures is huge, they can make a substantial contribution towards improving performance gains for precision manufacturing strides.

G-YOUNG is a team that will provide customers with top quality machines. Each member is responsible for his or her work and takes the responsibility Welding fixture. The raw materials used in the production process, and final product of noodles machines are subject to scientific and rigorous quality inspections. Our technology and effort are hoped to bring you better products.

The production process starts from raw materials to the company inspection, production process inspection to product factory inspection, installation and maintenance services A complete quality assurance systems has been Welding fixture the raw materials are checked strictly in accordance with the quality standards of the relevant standards in the country; Installation teams of the company are strictly adhered to the process of construction installation, and regular maintenance and security of installers are trained to master.

WUHAN G-YOUNG INDUSTRY(tm) CO. LTD. has more than 150 employees, more Than 10 Technical Managers. RD Engineers Over 20people. The RD team is many years of experience and superior quality. We have three Welding fixture production facilities with a capacity of between 2 and 14 tons of wheat flour consumption. the most advanced processing equipment from all over the globe. We can offer you the best noodle maker according to your requirements.

WUHAN G-YOUNG INDUSTRY(tm) CO., LTD is a professional exporter and manufacturer which researches, Welding fixture and manufactures instant noodle machine and fine dried noodles machines, and related equipment. Our primary products include instant noodles that are fried or not, low-temperature drying noodle lines featuring chain cables and hanging wires as well as fresh noodles production and other noodle equipment.