×

×

Metal working is the process of working with metals to create individual parts, assemblies or large scale structures. Welding Metals many other useful metal fabrication processes are followed by welding Metal pieces. Welding jigs are crucial to the effective work of welders. Welding jigs help in ensuring that the metal pieces stay steady and is rightly positioned over runs, significantly aids to create a higher quality end product consistently. It is important for us to understand the importance Fugao jig manufacturing if we want our welding project go success.

In the realm of welding, there are endless options for choosing your best-suited in line welder. The Fugao is one of the most popular choices because its rugged construction, along with a variety of adjustable options to meet any welding requirements.

How to Make a Welding Jig?

Making your own metal welding frame jig can be a fun and rewarding project to undertake. First let's collect some stuff: angle iron, square tubing, sheet metal and a welder. Here are some steps on how to mount your custom cylinder jig -

Begin by cutting the square tubing and angle iron to your specifications.

Cut the big sheet metal into smaller portions so that it is easy for welding.

Make the frame out of angle iron, and strengthen your corners to make sure it is durable.

Put the square tubing to use in bracing and it becomes simple to clamp workpieces firmly into position. It also uses the same techniques professional welders use to keep projects level and stationary.

Make sure that a welding jig is flat, in position and prepared for use at all points before you start to weld.

Improving Quality, Cost and Delivery Through Automation Welding Jigs

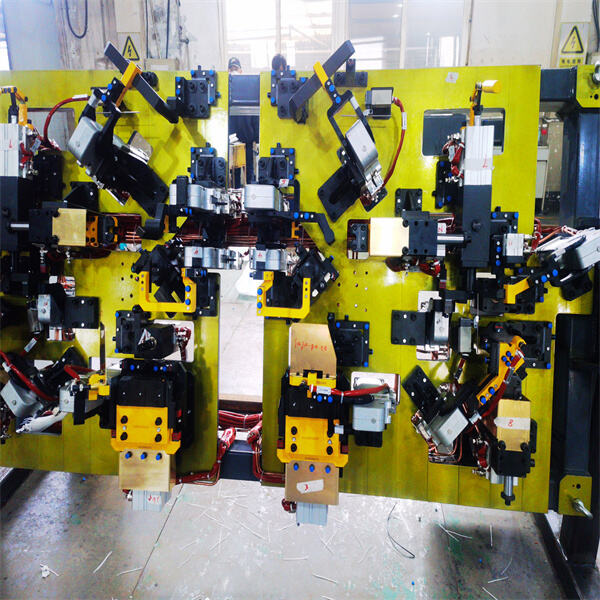

Improving Quality and Production Rates with welding jig and fixture. The fixtures in question assist the welding process by keeping workpieces welded optimally, ensuring errors are minimized and that only precise results make it out of the gate. On top of that, the unloading and suspected set up times quicker turnaround standard change work yet is just so speedy arrangement without any welders to begin with holders diminished expense.

Use the top tricks to improve your skills using Fugao welding jigs from professional.

Clamp your weldments or hold them together with bonding compound so they do not move during the welding process.

Fit all parts correctly before welding to avoid variations in the final weldment

Utilize proven welding jig fixture procedures and best practices to reduce the chances of errors during fabrication.

Protective blankets during welding to prevent heat and spatter

Welding Framing Tables Have Gotten Better. There have been some recent advances in welding the table you might find neat that can make all of this simpler. These are also new, replacing the old school twist-type clamps with mag welders that literally helped align your work. These modular designs allow fabricators to tweak the welding setups, taking help where needed from modern digital measurement and alignment tools, are yielding precision in a way that had never been possible. The only standardization, less waste and more efficient production will happen when you use the welding jigs tool in your factory to make sure that skilled works are also excelling at their best.

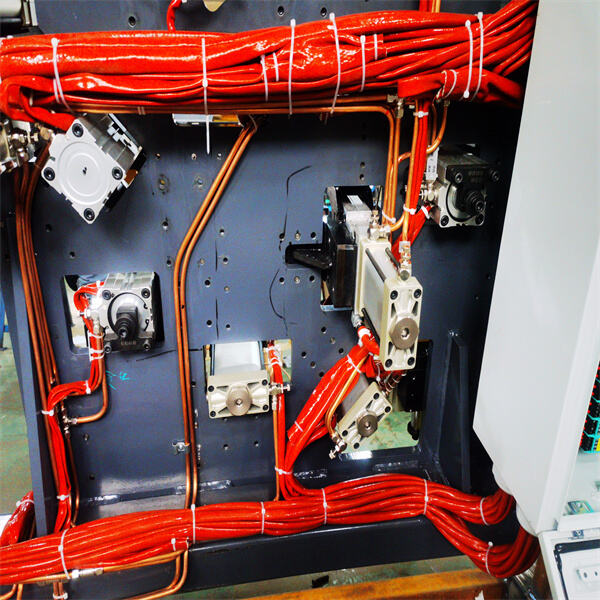

In the production Welding framing jig from raw materials through the company inspection, production process inspection to manufacturing facility inspection, maintenance and installation services An impeccable quality assurance procedures has been established: raw materials are inspected strictly in accordance with the quality requirements of the relevant national standards; The company installation team is strictly adhering to the process of construction installation, the regular inspection of the quality and safety of installers to be trained.

WUHAN G-YOUNG INDUSTRY(tm) CO. LTD. has more than 150 employees, more Than 10 Technical Managers. RD Engineers Over 20people. The RD team is many years of experience and superior quality. We have three Welding framing jig production facilities with a capacity of between 2 and 14 tons of wheat flour consumption. the most advanced processing equipment from all over the globe. We can offer you the best noodle maker according to your requirements.

G-YOUNG is committed to offering the finest quality machines. Each member of the team is devoted to their work and Welding framing jig for their every works. The raw materials, the production processes and final products produced by noodle machines will undergo scientific and stringent quality checks. Our expertise and technology are hoped to bring you better products.

WUHAN G-YOUNG INDUSTRY(tm) CO., LTD is a professional Welding framing jig and exporter which researches, designs and produces instant noodle machines as well as fine dried noodles machines, and other related equipment. Our primary products include instant noodles, both fried and unfried dry noodle lines at low temperatures featuring chain cables and hanging wires and fresh noodles production and other noodle equipment.