×

×

What you need in Welding Tables and Fixtures?

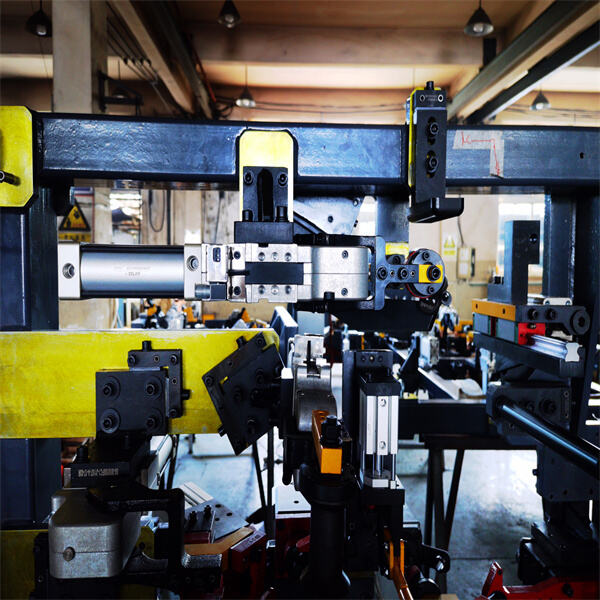

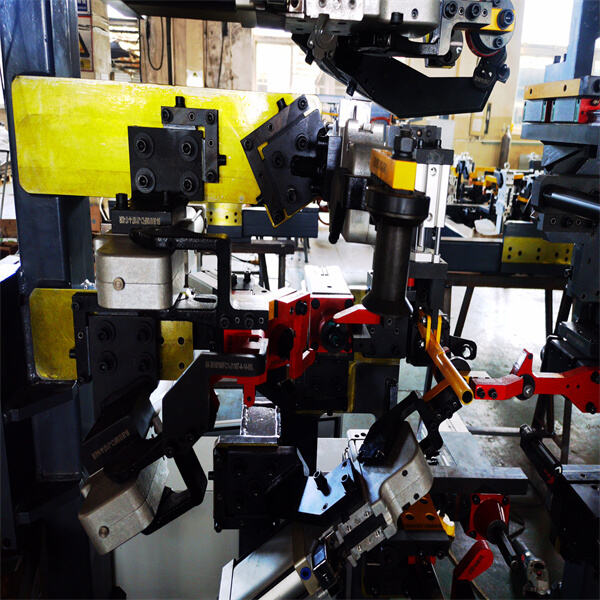

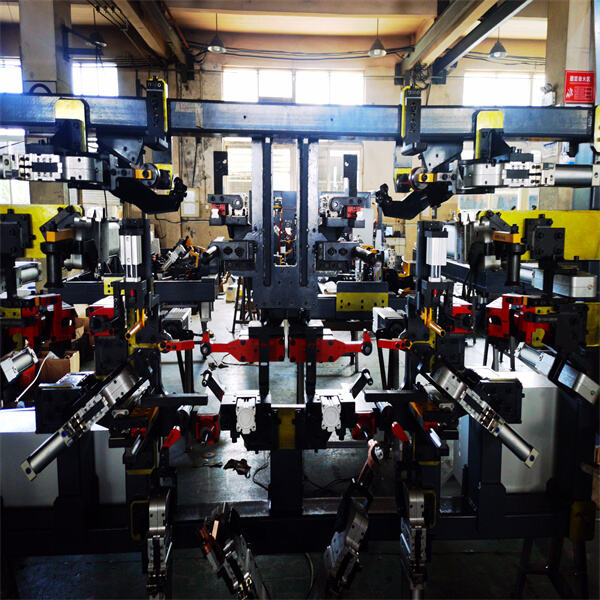

In manufacturing, welding is the process of joining similar metals through heat and pressure. One of the most important reasons to have a strong cart is because we must ensure welding takes place accurately and safely. how important role welding or holding table and fixture plays.

A welding table is the ground on which you do your work securely. Constructed from materials like steel, Aluminum or magnesium, and they offer support for the welding process by being strong of heat. By contrast, welding fixtures are tools of the trade intended to lock down pieces so they will maintain their positions during a weld cycle and not budge accidentally.

If you are a beginner in welding line, the most important thing is to buy one set of good quality fixturing system with adjustable fixtures and other components like weld tables, similar to the Fugao's product like cnc machining automotive parts. This makes the welding process easier, and improves precision as well efficiency.

If you are just getting started with welding and do not want to spend a lot of money on something like professional weld tables, there still maybe some great DIY ideas for workbenches. But just start with these 10 welding table ideas for beginners:

Wooden Welding Table: This solid table has a wooden frame and metal top for long-lasting service.

This is a general-purpose welding table that can be as versatile and portable by using sawhorses for legs, with an optional hinged top to house the welder.

Better yet, angle iron welding table: Piece together some angled iron and create a work surface that weighs very little but has the potential to handle much larger jobs, just like the rotating welding fixture produced by Fugao.

Pack n Weld Table: Conversion of a folding table into an easy to move metal top welding station.

Durable Welding Table: Create an indestructible table featuring a heavy metal top and square tubing legs, this so it won' be wobbling.

Adjustable Welding Table - Table that has an adjustable top which can be rotated and angled to suit the best position for your welding process.

Build a Modular Welding Table From Steel Tubing and Angle Iron for Slats

Welding Cart w/ Welder Table did a great job on this compact and mobile welding station.

Space Saving Welding Table Idea: Small footprint design with metal table top and folding legs fits within tight spaces.

DIY Workbench Welding Table: Screw down a metal top to create welding workspace on an existing work bench.

TIG welding is precise and so it requires very specific tools to get that level of quality in your welds.

Tools a Welder Cannot Live Without

Whether you are an experienced professional or just getting started in the world of welding, here is what equipment every welder needs to achieve good results.

Welding Clamps-Welding clamps hold workpiece during welding and support it, also the Fugao's product such as welding angle jig.

Magnets - Welding magnets are perfect for holding metal pieces together when your weld creates a flat surface of the right height.

Square holds at perpendicular welds ensuring every workpiece is at right angles to its neighbour; resulting in levels of accuracy from your welding that is truly unheard of.

Angle Gauge: For accurate angle of measurement, leading to in-time welds.

Metal File: It is used to give a proper finishing and smoother edges for good welding.

Chipping Hammer: Mandatory for knocking-off the mess and slag from weld areas to make clean, strong Welds.

Welding Pliers: Aid in controlling and aligning work pieces through the welding operation.

Level: This is so the worktop surface is flat otherwise your welds are going to be all wonky.

As a welder that works in heavy-duty projects, you should see to it that the welding table is stout enough and capable of holding even larger workpieces, along with the pallet assembly jig supplied by Fugao.

A welding table allows welders customize their workspace to the requirements and preferences of a specific project. Below, we present a few of the ideas for how you can set about constructing your own customized welding table:

Limitless Top: Choose the worktop that best suits your welding style, such as stainless steel or Aluminum, similar to the Fugao's product like welding jig fixture.

Height: Implement height settings to the table for added convenience and comfort when welding.

Similarly, another organization tip is to add tool storage like drawers or shelves for storing tools and other equipment in an organized manner.

Your Welding Table Will be Easy to Move Around If You Have Wheels

Adding wheels or casters make it convenient essential if you have a small workshop

Custom Clamping Systems. Add your own customized clamps, magnets or fixtures to guarantee workpieces stay secure while welding.

Finally, both welding tables and fixtures are essential tools that welders need if they want their work to go smoothly. Choosing the right welding table will allow you to get your work done proficiently, and it should have all or some of these features: Durability built in, practical design for storage options, portability with adjustability included within its setup at any height including angles that throws off gravity while still having a sturdy clamp system. The proper tools and equipment go a long way in improving the welding experience - As DIY welding table ideas, high-quality top rated tables or personalized designs will make all your tasks easier to complete with outstanding efficiency.

G-YOUNG is a team that will provide customers with top quality machines. Each member is responsible for his or her work and takes the responsibility Welding tables and fixtures. The raw materials used in the production process, and final product of noodles machines are subject to scientific and rigorous quality inspections. Our technology and effort are hoped to bring you better products.

The production process, from the raw material to the company inspection and inspections during the manufacturing process, through inspections at the factory of the product Installation and maintenance has developed a Welding tables and fixtures control system: Raw materials are strictly inspected according to the quality requirements of applicable standards of the national standard. Installation teams of the company strictly follow the construction process, and regular safety and quality of installation workers.

Welding tables and fixtures has More than 150 employees. More Than 10 Technical Managers. RD Engineers Over 20people. The RD staff has years of knowledge and experience, as well as high-quality. We have three large production facilities with a capacity of between 2 and 14 tons of wheat flour consumption, and more than 1000 advanced processing equipments from across the globe. We will give you the best noodle maker according to your requirements.

WUHAN G-YOUNG INDUSTRY(tm) CO., LTD is a professional Welding tables and fixtures and manufacturer which researches, designs and manufactures instant noodles machines as well as fine dried noodles machines, as well as other equipment. Our main products include instant noodles, both fried and unfried production lines, low temperature hanging and chain cable-style drying noodle production lines, and freshly made noodles production lines in addition to other equipment used in the production of noodles.